Effect of Hybridization on the Tensile Properties of S-glass Fibre/Nanoclay/Epoxy Composites

DOI:

https://doi.org/10.62050/ljsir2025.v3n2.597الكلمات المفتاحية:

Hybrid-composite، Nano-composite، Epoxy، Nanoclay، S-Glass Fibre، Tensile Propertiesالملخص

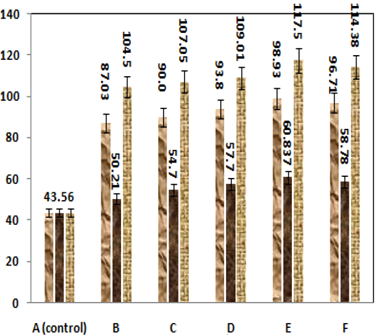

three groups of composites were fabricated: glass/epoxy composites A, B,C,D,E and F which contains 0, 10, 20, 30, 40 and 50 wt. % glassfibre reinforcement respectively. Naonclay/epoxy composite B, C, D, E and F, with 0, 1, 2, 3, 4 and 5 wt.% nanoclay content respectively. Hybrid composites B, C,D, and F, contain equal amount of epoxy ( 60 wt. %), 39, 38, 37, 36, and 35 wt. % glassfibre and 1, 2, 3, 4, and 5 wt. % nanoclay content respectively. Sample A is the Control sample with 100 wt. % epoxy. Tensile properties of S-glassfibre/nanoclay/epoxy hybird nanocomposite E, which contains 60 wt. % epoxy, 4 wt & nanoclay and 36 wt. % glassfibre was found to be the overall best performing composite in the mechanical properties.

التنزيلات

المراجع

Zhu, W., Bartos, P. J. M., and Porro, A., (2014). “Application of nanotechnology in construction” materials and structures, vol. 33 pp 649-658.

Zuradia, A., norshahida, S., sopyan, I., Zahurin, H, (2021). “Effect of fibre length variation on coir fibre reinforced cement-albumen composite”, IIUM eng. J., 1263-75.

Yuanjian T. and Isaac D. H. (2008) Combined impact and fatigue of glass fiber reinforced composites. Compos Part B 2008;

Riedel, U. and Nickel, J. (2016) “Applications of Natural Fibre Composite for Constructive Parts in Aerospace, Automobiles and Other Areas” joerg.nickel@dlr.de

Venkateswarulu, (2018). “Composites – a review” Journal of Reinforced Plastics and Composites 2014, Vol. 33(13) 1258–1275

Rashim, .G and Nijagal, A (2018) “Strength Characterization of E-glass Fiber Reinforced Epoxy Composites with Filler Materials”, Journal of Minerals and Materials Characterization and Engineering,

Shiamaa, H., Abd-Elrahman and Mustafa, M. A. M. (2015). “Application of nanotechnology in agriculture an overview”, Egyupt Journal of social science 5(2):2

Patel, B. S, Emami, S. and Gabil, H. (2022). “Thermal and mechanical properties of blends and composites from LDPE and date pits particles,” Journal of Composite Materials, 40 (1): 80–89

Riedel, U. and Nickel, J. (2016) “Applications of Natural Fibre Composite for Constructive Parts in Aerospace, Automobiles and Other Areas” joerg.nickel@dlr.de

Njuguna, J. and Alcock, K. P. (2018). “Epoxy-Based Fibre Reinforced Nanocomposites” Adv. Eng. Mater. 9,835-847

Parida, A. K., Bhatta, V. R., Martha, B. K., Nayak, B. and Mohanta, R. K., (2013) “Static mechanical properties of GFRP laminates with fly ash and graphite as filler material”,Int. J. Adv. Res. Sci. Technol. Volume 2, Issue1, 22-26

Li Z, Wang, L. and Wang, X. (2016). “Flexural characteristics of coir fibre reinforced cementitious composites”. Fibers Polym., 7(3) 286-294

Mohbe, M., Singh, P. and Jain, S. K. (2012). Mechanical characterization of Na-MMT glass fiber reinforced polyester resin composite. Int J Emerging Techno Advanced Eng 2012; 2: 702–707.

Kumaresan, M., Sathish, S. and Karthi, N. (2015) “Effect of Fibre Orientation on Mechanical Properties of Sisal Fiber Reinforced Epoxy Composites” Journal of Applied Science and Engineering Vol. 18, No. 3, Pp. 289-294.

Man-Wai H., Chun-Ki, L., Kin-tak, L., Dickon, H. L. N., David, H., (2016) “Mechanical properties of epoxy-based composites using nanoclays”, Composite Structures 75 pp. 415–421.

Karakuzu R., Erbil E. and Aktas M. (2020) “Impact characterization of glass/epoxy composite plates: an experimental and numerical study”. Compos Part B 2020; 41: 388–395.

Kusmono, Wildan, M. W, and Mohd-Ishak, Z. A. (2013) “Preparation and Properties of Clay-Reinforced Epoxy Nanocomposites” International Journal of Polymer Science Volume 2013, Article ID 690675, 7

Hussain A. J., Dhafir A. S. and Abdul-Jabar A. H. (2022) “Fatigue behaviour of woven glass fibre reinforced polyester under variable temperature”. Elixir mech Eng 2022; 53: 12045–12050.

Kamel, S. (2007) “Nanotechnology and its applications in lignocellulosic composites, a mini review” Express Polym. Lett.1, 546-575.

Hameed N, Sreekumar P. A. and Francis, B. (2017). ”Morphology, dynamic mechanical and thermal studies on poly (styrene-co-acrylonitrile) modified epoxyresin/glass fibre composites”. Compos Part A 2017; 38: 2422–2432.

International Standard Organization ISO (2018). “Nanotechnologies-Terminology and Definitions for Nano- Objects, Nanoparticles, Nanofibre and Nanoplate” ISO/TS 27687 Geneva, Switzerland.

Deshpande, S. and Rangaswamy, T.(2014) “Effect of Fillers on E-Glass/Jute Fiber Reinforced Epoxy Composites”, Int. Journal of Engineering Research and Applications, , pp.118-123

Etmimi, H.M. (2012) “New approaches to the synthesis and exfoliation of polymer/ functional grapheme nanocomposite by miniemulsion polymerisation”. A dissertation presented for the degree of doctorate of philosophy in polymer science at the University of Stellar Bosch.

Cervalho, Kelly C.C., Mulinari, Danieua R., Voorwald, Herman J.C., Coiffi, and Maia O. (2020) “Chemical modification effect on the mechanical properties of HIPS/Coconut fibre reinforced composites”, BioRes. 5(2) 1143-1155

Al-Mosawi, S. M. and Tabil, L. G. (2012) “Thermal and mechanical properties of blends and composites from HDPE and date pits particles,” Journal of Composite Materials, 42 (1): 77–89,

Baucom J. N., and Zikry M. A. (2015) “Low velocity impact damage progression in woven E-glass composite systems”. Compos Part A 2015; 36: 658–664.

Haydon, B. and Eng. P. (2012) “Nanomaterials and their applications in textiles – standards”. Domestic standardization for Canadian Manufactures, importers and international standardization Development. Cat. No:1a44-87/2012EPDF, ISBN 978-1-100-21089-6: www.ic.gc.ca/textile

Atas C and Liu D. (2018) “Impact response of woven composites with small weaving angles”. Int J Impact Eng 2018; 35: 80–97.

التنزيلات

منشور

إصدار

القسم

الرخصة

الحقوق الفكرية (c) 2025 Bisike Chidiebere Egere, Lawal Omeiza Yusuf, Philip Abubakar, Sunday Adaogoshi Eya, Catherine Okaigbo Oseshi (Author)

هذا العمل مرخص بموجب Creative Commons Attribution-ShareAlike 4.0 International License.