Fabrication and Characterization of Baobab Pod (Adansoniadigitata) FiberReinforced Polyester Resin Composite

DOI:

https://doi.org/10.62050/ljsir2024.v2n2.304Keywords:

Polyester, resin, Unsaturated, Baobab, FabricationAbstract

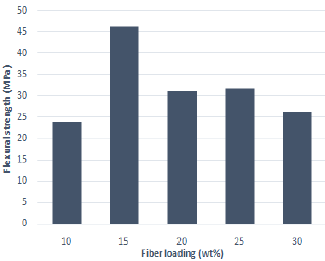

Baobab pod fibres were obtained from Sabo market in Zaria and sliced longitudinally, screened out from the baobab fruit, washed with water, dried under sun for fabrication and characterization. The fiber was extracted and treated with 5% NaOH solution. Important samples were fabricated with different fiber loading of 10wt%-30wt%. The samples were moulded using Hand Lay-up method followed by pressing and post cured at 60oC for 3 hours. The result showed tensile strength decreases as the loading of fiber increased from 20 wt% to 30 wt%. It was also observed that baobab composite has the highest tensile strength of 18.85 MPa at 20 wt% and least (16.45 MPa) at 15 wt%. The result also revealed the elongation at break increased from 20 wt% to 25 wt%. At 25wt% it has a maximum value (18.4%) elongation at break; at 30wt%. It was also observed that the density increased with increase in the fiber loading from 15wt% to 30wt% (1.23g/cm3 - 2g/cm3) respectively. At 15wt% shows a maximum water take-up of 6.53% while from 20 wt% to 30 wt%, Flexural strength increased from 10 wt% to 15 wt% (23.98MPa - 46.3Mpa). However, the bending stress decreases on increasing the fiber loading from 20-30 wt% (30.2 Mpa – 25.2 Mpa). The elastic nature of the composite generally increases with increased in fiber loading. This study, however recommend hybridization of baobab pod fiber with other natural fiber to investigate the mechanical and physical property of the hybrid composite for better result.

Downloads

References

Alsubari, S., Zuhri, M. Y. M., Sapuan, S. M., Ishak, M. R., Ilyas, R. A. & Asyraf, M. R. M. (2021). Potential of natural fiber reinforced polymer composites in sandwich structures: a review on its mechanical properties. Polymers, 13(3), 423. https://doi.org/10.3390/polym13030423

Abdulkhalil, H. P. S., Bhat, I. U. H., Jawaid, M., Zaidon, A., Hermawan, D. & Hadi, Y. S. (2012). Bamboo Fibre Reinforced Biocomposites: A review. Materials and Design, 42, 353-368. https://doi.org/10.1016/j.matdes.2012.06.015

Jawaid, M., Abdul & Khalil, H. P. (2011). Cellulose/synthetic fibre reinforced polymer hybrid composites. School of Industrial Technology, 86(1), 1-18. https://doi.org/10.1016/j.carbpol.2011.04.043

Dipto, C., Md Shariful, I., Kazi, J. & Md Rashedul, H. S. (2020). Effect of chemical treatment on the mechanical properties of luffa fiber reinforced epoxy composite. Journal of Engineering Advancements, 01(01), 37-42. https://doi.org/10.38032/jea.2020.02.002

Joerg, B., Ren Zhongqi & Fei, W. (2005). Ternary diffusion coefficients of 1-hexanol-hexane tolueneand 1-propanol-water-ethylene glycol by Taylor dispersion method. Tsingua Science and Technology, 10(5), 523-528

Kaboré, D., Sawadogo-Lingani, H. & Diawara, B. (2011). A review of baobab (Adansoniadigitata) products: Effect of processing techniques, medicinal properties and uses. .African Journal of Food Science, 5(16), 833-844. https://doi.org/10.5897/AJFSX11.00

Sibibe, M. & Williams, J. T. (2002). Baobab – AdansoniadigitataL., p. 96. Southampton, UK: International Centre Underutilized Crops

Selma, B., Bannari, R. & Proulx, P. (2010). A full integration of a dispersion and interface closures in the standard model of turbulence. Chemical Engr. Sci., 65(20), 5417-5428. https://doi.org/10.1016/j.ces.2010.06.020

Kabbashi, N. A., Mirghani, M. E. S., Alam, Md. Z, Sam, Y. Q. & Ibrahim, A. B. (2017). Characterization of the baobab fruit shells as adsorption material. International Food Research Journal, 24(Suppl.), S472-S474. http://www.ifrj.upm.edu.my

Shehu, U., Isa, M. T., Aderemi, B. O. & Bello, T. K. (2017). Effects of NaOH modification on the mechanical properties of baobab pod fiber reinforced LDPE composites. Nig J. of Techn., 36(1), 87-95. https://doi.org/10.4314/njt.v36i1.12

ASTM Literature References for Composite Materials 1st edition, ASTM International West Conshohocken. Philadelphia USA, 1987

Kumar, R., Obrai, S. & Sharma, A. (2011). Chemical modifications of natural fibre for composite material. Der ChemicaSinica, 2(4), 219-228. https://www.researchgate.net/publication/285777182

Prakash, K. B., Fageehi, Y. A., Saminathan, R., Manoj Kumar, P., Saravanakumar, S., Subbiah, R., Arulmurugan, B. & Rajkumar, S. (2021). Influence of fiber volume and fiber length on thermal and flexural properties of a hybrid natural polymer composite prepared with banana stem, pineapple leaf, and S-glass. Advances in Mat. Sci. and Engr., 2021, 1-11. https://doi.org/10.1155/2021/6329400

Sathishkumar, T. P., Satheeshkumar, S. & Naveen, J. (2014). Glass fiber-reinforced polymer composites - A review. Journal of Reinforced Plastics and Composites, 33(13), 1258–1275. https://doi.org/10.1177/0731684414530790

Siddika, S., Mansura, F., & Hasan, M. (2013). Physico-mechanical properties of jute-coir fiber reinforced hybrid polypropylene composites. International Journal of Chemical, Molecular, Nuclear, Materials and Metallurgical Engineering, 7(1), 60-64

Parasana, V. R., Ramanathan, K. & Srinivasa, R. S. (2016). Tensile, flexural, impact and water absorption properties of natural fiber reinforced polyester hybrid composites. International Journal of Modern Engineering Research (IJMER), 24(3), 90-94. https://doi.org/10.5604/12303666.1196617

Downloads

Published

Issue

Section

License

Copyright (c) 2024 Lafia Journal of Scientific and Industrial Research

This work is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License.