LINEAR PROGRAMMING APPROACH TO MODELING FOUNDRY CUPOLA FURNACE CHARGE

Keywords:

Cupola, Foundry, Furnace charge, Optimization, Linear ProgrammingAbstract

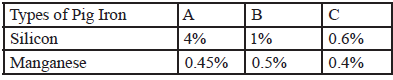

In order to control the specifications of the cast iron produced by the cupola furnace, it is necessary to estimate the proportions of the contents of the furnace charge. Traditionally, knowing the percentage of elements present in each constituent of charge and the loss or gain of each element, the final analysis of cast iron can be estimated by trial and error approach - a common approach in most Nigerian foundry workshops. This study presents a programming model technique used to obtain the optimum cupola furnace charge. The objective function was to minimize total cost of raw material and processing costs. The model was developed and implemented using the hypothetical process data of a Foundry workshop. The model was analysed using MATLAB Software Version 7.0. The results obtained using the model is significantly superior to the conventional trial and error approach. It is faster and brings about satisfying a lot of requests at the most minimal expense.

Downloads